Finned Elements

DDR Heating's finned heating elements are used in applications where higher watt densities are required for higher heat demands. The fins allow for rapid heat disbursement, allowing for a maximum amount of heat from the heating element. These heaters are traditionally used in the comfort and control industry in both commercial and residential application such as: Baseboard Heaters, Comfort Heaters, Space Heaters, Draft Barrier Heaters, Wall Mounted Heaters and Radiant Heaters.

Finned Electro-Heater Assemblies

- Steel fins copper brazed to steel sheath heating element

- .315” diameter steel sheath heating elements

- 1 to 3 heating elements in hair pin formation

- 1 to 6 heating elements in straight formation

- 22 gauge steel fins. Fin sizes: 3 1/2”x 1 ½” & 2” x 4”

- Standard fin spacing: ¼”. ½” spacing available upon request

- Terminal configuration to customer specifications

- 3” minimum & 11” maximum fin length = 13 to 45 fins

- UL & CSA approved

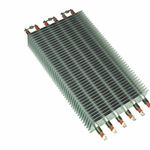

Finned Electro-Heater Assembly

Straight Heating Elements

- Steel fins copper brazed to steel sheath heating elements

- .430” diameter straight heating elements

- 2 or 3 straight heating elements per assembly

- 22 gauge steel fins. Fin sizes: 3 ½” x 1 ¾” & 4 1/8” x 1 5/8”

- ¼” standard fin spacing. ½” spacing available upon request

- Terminal configurations to customer specifications

- 8” minimum & 47” maximum fin length = 33 to 189 fins

- UL & CSA approved

Finned Electro-Heater Assembly

2” x 6” Steel Fins

- Steel fins copper brazed to steel sheath heating elements

- .430” diameter straight heating elements

- 2 to 6 straight heating elements per assembly

- 22 gauge steel fins. Fin sizes: 2” x 6”

- ¼” standard fin spacing. 1/2” spacing available upon request

- Terminal configurations to customer specifications

- 8” minimum & 22” maximum fin length = 33 to 89 fins

- UL & CSA approved

Spiral Finned Heating Elements

- Steel strip copper brazed to steel sheath heating elements

- .260’, .315” & .430” Sheath diameters available

- 130” maximum length

- Bend configurations and termination to customer specifications

- UL & CSA approved